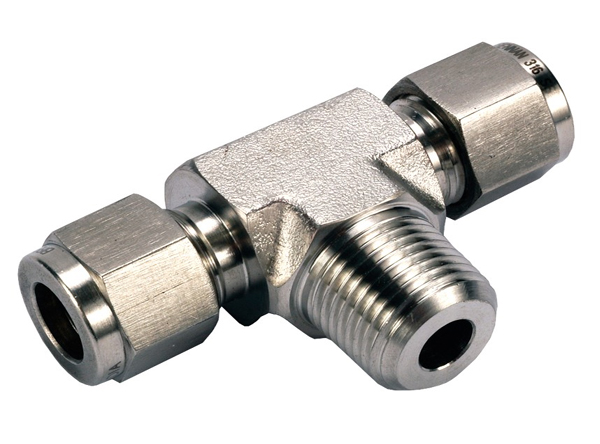

MALE BRANCH TEE

We manufacture, supply and export Male Branch Tee Fittings which are very useful in various types of connecting functions in the big industries. Our Male Branch Tee fittings are of four types to be used in many different works in the varied industries.

Our in-house production of Male Branch Tee is manufactured with excellent quality of raw materials to suit the fixing work mainly in electrical industries, air conditioning industries. These products of ours have been well demanded and extensively used by the clients of diverse category in different size. These Male Branch Tee have part numbers of numerous kinds to select from.

A Male Branch Tee is a T-shaped pipe fitting with male threads on all three connections. It is used to divide or combine fluid or gas flow in piping systems, connecting one inlet to two outlets or vice versa. These fittings are essential for creating a three-way connection in various industrial applications.

Features of Male Branch Tee

- Durable Construction: NPT Male Branch Tee fittings are available in materials such as Stainless Steel Male Branch Tee and Brass Male Branch Tee, offering excellent resistance to corrosion, temperature, and pressure.

- Versatile Connections: The Male Branch Tee Fitting allows for easy connection of pipes or hoses with male threads, making it suitable for various industrial systems.

- High-Pressure Compatibility: The High-Pressure Male Branch Tee is designed to handle high-pressure environments, ensuring leak-proof connections in demanding applications.

- Multiple Configurations: Available in different configurations such as Male Branch Pipe Tee, Male Branch Hose Tee, and Male Branch Threaded Tee, these fittings cater to different industry needs.

- Reliable Performance: Hydraulic Male Branch Tees and NPT Male Branch Pipe Fittings ensure consistent, reliable performance in hydraulic, pneumatic, and fluid transfer systems.

Applications of Male Branch Tee

- Oil and Gas Industry: NPT Male Branch Tees are used in pipelines and refineries to distribute fluids or gases into multiple directions.

- Hydraulic Systems: Hydraulic Male Branch Tee fittings are essential for creating secure connections in hydraulic systems, allowing for smooth flow division.

- Chemical Processing: The corrosion-resistant properties of Stainless Steel Male Branch Tees make them ideal for use in chemical processing plants.

- Water Treatment Plants: Male Branch Tee Adapters are commonly used in water treatment facilities to regulate and manage water flow through piping systems.

- Manufacturing and HVAC: Male Branch Pipe Tees are used in HVAC systems and industrial manufacturing processes to ensure efficient distribution of air, gas, or liquids.

Why Choose McNeil Instruments for Male Branch Tee?

McNeil Instruments is a leading Male Branch Tee Supplier, Manufacturer, and Exporter, offering high-quality piping solutions across various industries. Here’s why you should choose us:

- Premium Quality Materials: We offer Stainless Steel Male Branch Tees, Brass Male Branch Tees, and more, ensuring long-lasting durability and excellent corrosion resistance.

- Wide Range of Products: Our extensive product line includes NPT Male Branch Tees, Male Branch Tee Connectors, and Male Branch Hose Tees, providing a solution for every application.

- Custom Solutions: As a reliable Male Branch Tee Manufacturer, we offer custom solutions tailored to your specific piping requirements.

- Global Reach: As a trusted Male Branch Tee Exporter, Mcneil Instruments serves clients worldwide, ensuring timely delivery and exceptional customer service.

- Cost-Effective Solutions: We provide high-quality Male Branch Tee Fittings at competitive prices, giving you the best value for your investment.

For top-quality Male Branch Tee fittings that ensure reliable performance, choose McNeil Instruments. Contact us today to learn more!

Products

| Mcneil part no. | Equivalent Part no. Type 1 | Equivalent part no Type 2 | NPT FEMALE PIPE SIZE P | LX | ODT-ØT(INCHES) | Ø E | BODY HEX F | C | NUT HEX W | D | L1 |

| 2-MBTD-2N | -200 – 3 – 2TTM | 2MBT2N | 1/8 | 0.70 | 1/8 | 0.09 | 9/16 | 0.60 | 7/16 | 0.50 | 1.86 |

| 2-MBTD-4N | -200 – 3 – 4TTM | 2MBT4N | 1/4 | 0.92 | 1/8 | 0.09 | 9/16 | 0.60 | 7/16 | 0.50 | 1.94 |

| 3-MBTD-2N | -300 – 3 – 2TTM | 3MBT2N | 1/8 | 0.70 | 3/16 | 0.12 | 9/16 | 0.63 | 7/16 | 0.54 | 1.92 |

| 4-MBTD-2N | -400 – 3 – 2TTM | 4MBT2N | 1/8 | 0.74 | 1/4 | 0.19 | 9/16 | 0.70 | 9/16 | 0.60 | 2.12 |

| 4-MBTD-4N | -400 – 3 – 4TTM | 4MBT4N | 1/4 | 0.92 | 1/4 | 0.19 | 9/16 | 0.70 | 9/16 | 0.60 | 2.12 |

| 5-MBTD-2N | -500 – 3 – 2TTM | 5MBT2N | 1/8 | 0.82 | 5/16 | 0.19 | 9/16 | 0.73 | 5/8 | 0.64 | 2.34 |

| 5-MBTD-4N | -500 – 3 – 4TTM | 5MBT4N | 1/4 | 1.01 | 5/16 | 0.19 | 9/16 | 0.73 | 5/8 | 0.64 | 2.34 |

| 6-MBTD-4N | -600 – 3 – 4TTM | 6MBT4N | 1/4 | 1.00 | 3/8 | 0.28 | 13/16 | 0.86 | 11/16 | 0.66 | 2.40 |

| 6-MBTD-6N | -600 – 3 – 6TTM | 6MBT6N | 3/8 | 1.11 | 3/8 | 0.28 | 13/16 | 0.76 | 11/16 | 0.66 | 2.62 |

| 8-MBTD-6N | -810 – 3 – 8TTM | 8MBT6N | 3/8 | 1.11 | 1/2 | 0.38 | 13/16 | 0.86 | 7/8 | 0.90 | 2.84 |

| 8-MBTD-8N | -810 – 3 – 8TTM | 8MBT8N | 1/2 | 1.30 | 1/2 | 0.41 | 13/16 | 0.86 | 7/8 | 0.90 | 2.84 |

| 10-MBTD-8N | -1010 – 3 – 8TTM | 10MBT8N | 1/2 | 1.41 | 5/8 | 0.47 | 1 | 0.86 | 1 | 0.96 | 3.06 |

| 12-MBTD-12N | -1210 – 3 – 12TTM | 12MBT12N | 3/4 | 1.45 | 3/4 | 0.62 | 1-1/16 | 0.86 | 1-1/8 | 0.96 | 3.14 |

| 14-MBTD-12N | -1410 – 3 – 12TTM | 14MBT12N | 3/4 | 1.50 | 7/8 | 0.62 | 1-3/8 | 0.86 | 1-1/4- | 1.02 | 3.52 |

| 16-MBTD-12N | -1610 – 3 -12TTM | 16MBT12N | 3/4 | 1.66 | 1 | 0.62 | 1-3/8 | 1.04 | 1-1/2 | 1.23 | 3.88 |

| 16-MBTD-16N | -1610 – 3 -16TTM | 16MBT16N | 1 | 1.84 | 1 | 0.88 | 1-3/8 | 1.04- | 1-1/2 | 1.23 | 3.88 |

Monel :

Grade: Monel 400, Monel K500, Monel R-405

Nickel :

Grade: Nickel 200, Nickel 201

Inconel :

Grade: Inconel 600, Inconel 601, Inconel 625, Inconel 718

Incoloy :

Grade: Incoloy 800, Inconel 800H, 800HT

Hastalloy :

Grade: Hastalloy B2, Hastalloy B3, Hastalloy C22, Hastalloy C276, Hastalloy X

Titanium :

Grade: Gr1, Gr2, Gr3, Gr5, Gr7, Gr11

Stainless Steel :

Grade: ASME / ASTM SA / A403 SA / A 774 WP-S, WP-W, WP-WX, 304, 304L, 316, 316L, 304/304L, 304H, 316H, 316/316L, 321, 330, 347, 309/S, 310/S, 317/L, 333, 410/S, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404

Carbon Steel :

Grade: ASTM A 234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70

Duplex Steel:

Grade: ASTM / ASME A/SA 182 UNS F44, F45, F51, F53, F55, F60, F61

Alloy Steel:

Grade : ASTM SA 182 – E25, E26, E27, E28, E29B, E30B, E39B, E40B, E36B, E36C, E41B, AISI4130, AISI4140, AISI4340, 42CRMO4, 16MNCR5, 20MNCR5, 21CrMoV57, EN353, EN354, F11, F22, F91, F9, P11, P22, P91, P9, P5, P92, EN42J, EN8, EN19