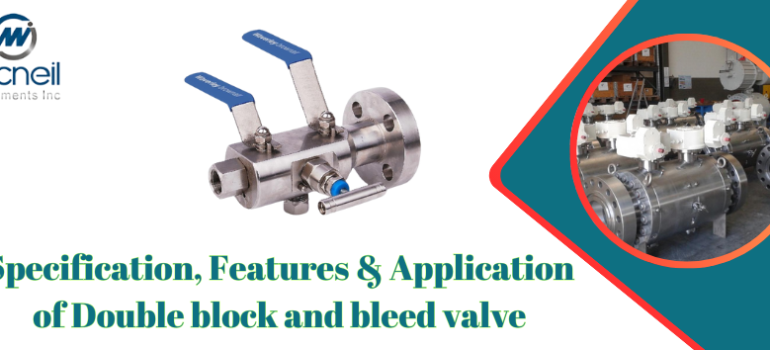

Specification, Features & Application of Double Block and Bleed Valve

The DBB valve is an acronym for the double block and bleed valve. It is composed of two regular ball valves connected by a shared input end. The product known as the double block and bleed ball valve, as its name implies, is designed to replace many connections between traditional valves. This DBB valve is different from the traditional one in that it can easily discharge, shut rapidly, and efficiently handle leaks that occur during system operation. This DBB ball valve is a contemporary type of valve that is widely available nowadays.

Types of Double Block & Bleed Valve

DBB valves can be divided into two primary categories based on their physical structure:

Split-body or modular DBB valves: The primary characteristic of this design is the use of two balls in a single valve to increase safety. On the Double Block & Bleed valve, a drain needle valve is situated in the space between the two balls. Piping valves come in sizes ranging from one inch to twenty-four inches, whereas instrumentation valves are sized between one and three inches. In every pressure class scores range from 150 to 2500 pounds, API 3.000 to API 10.000.

Integral DBB Valves: These valves are utilized in the instrumentation business and are available in a range of configurations, including The Integral Double Block & Bleed valve has a drain needle valve situated in the space between the two balls. This makes it possible to empty the valve and return the pressure to zero. ing injection, sampling, flange to flange, flange to thread, ball, and needle kinds, to suit different applications.

DBB Valve’s features and benefits :

In order to offer dual insulation, double block, and bleed valves have been devised in place of the traditional method of fastening the separate valves together.

Excellent weight, space, and installation time reductions are offered by this new model, especially when it comes to insulation inside the instrument or instrument cage. These weight savings might reach 60%, and testing has indicated that installation time savings of up to 70% are also feasible.

However, the largest advantage must be observed in the reduction of environmental leakage paths, which therefore lowers the likelihood of potential hazards.

When repair is carried out downstream of the first isolation valve, dual isolation is a must. Either a ball or a globe vent valve provides cavity venting, allowing the compressed pressure between the two isolation valves to be securely evacuated.

In addition, these valves now provide sampling points and chemical injection functions. These valves also have control valves built-in into them.

Additional Features of Double Block and Bleed Valve:

Design Variations: To meet diverse industrial needs, DBB valves are offered in a range of designs, including split-body, modular, and integrated.

Safety Improvement: By offering dual insulation and lowering potential risks, the use of two balls in a single-valve design improves safety.

Cavity Venting: Dual isolation valves help to ensure the safe evacuation of compressed pressure when they are employed downstream of the first isolation valve.

Additional Functions: DBB valves now provide additional functionalities like sampling points and chemical injection, making them versatile for various industrial applications.

Industrial Application of Double Block and Bleed Valve

DBB valves are utilized in situations where it’s essential to ensure that there are no leaks. These valves can be used in a wide range of sectors and applications, including petrochemical, transmission and storage, industrial operations involving natural gas, main-line and multipurpose valves in liquid pipelines, and refined material transmission lines.

Another usage for the DBB valve is the requirement for meter calibration. Tight sealing is required on every valve that is closed to the meter device. Large quantities of money are needed, and even a small leak can lead to inaccuracies in meter calibration. The erroneous meter factor persists until the next confirmed operation. Selecting the appropriate DBB or DIB valve tested for API will contribute to nearly always correct calibration.

Global Manufacturing Expertise:

With a wealth of experience, McNeil Instruments Inc. is a prominent global leader in the production of DBB valves. Our products meet international standards for precision and dependability, as a result of our dedication to quality. Being a reputable international manufacturer, we place a high value on quality, guaranteeing that our DBB valves work superbly in a variety of industrial applications.

Constant Innovation:

McNeil Instruments Inc. is committed to creating innovative products that keep their DBB valves at the forefront of valve technology. We ensure cutting-edge solutions that satisfy changing industry needs by implementing the most recent developments. Our dedication to innovation highlights our desire to provide DBB valves that are superior in terms of dependability, performance, and efficiency.

Conclusion

Double block and bleed ball valves isolate important parts of the apparatus to safeguard system integrity. Without affecting the device, you can examine, repair, or restore these sections. Numerous sectors, including petrochemical, water, oil and gas, and more, employ these valves. They may be modified and come in a variety of combinations. Depending on how and when you want to use it, you can select the appropriate DBB valve. As a Mcneil Instruments Inc. manufacturer of double block and bleed valves, NTGD valve invites you to contact us if you’re unsure which DBB valve would be best for your project.

#doubleblockbleedvalve #globalmanufacturing #industrial