Complete Guidance on Soft Copper Tube – Mcneil Instruments

Soft copper tubes are essential components in various industries, widely used for plumbing, refrigeration, and air conditioning systems. In India, they play a pivotal role in ensuring efficient and reliable operations across residential, commercial, and industrial sectors. In this comprehensive guide, we’ll delve into the intricacies of soft copper tubes, exploring their properties, applications, installation techniques, and maintenance practices in simple Indian English.

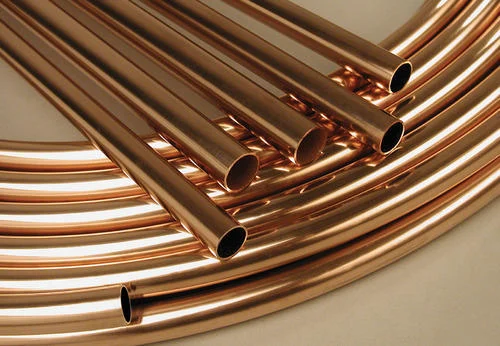

Introduction to Soft Copper Tubes

Soft copper tubes are versatile cylindrical conduits made from goods quality copper, a ductile metal renowned for its excellent thermal and electrical conductivity. These soft copper tubes are manufactured through a meticulous process involving the extrusion of copper billets into seamless soft copper tubes of varying diameters and thicknesses. The resulting product boasts remarkable malleability, allowing it to be bent and shaped without the risk of structural damage, making it ideal for intricate installations.

Properties of Soft Copper Tubes

- Malleability: Soft copper tubes exhibit exceptional malleability, enabling effortless bending and forming to accommodate complex layouts and configurations.

- Corrosion Resistance: Copper inherently resists corrosion, ensuring longevity and reliability, especially in environments prone to moisture and chemical exposure.

- Thermal Conductivity: With superb thermal conductivity, copper tubes facilitate efficient heat transfer, making them indispensable in refrigeration and air conditioning systems.

- Leak Resistance: The seamless construction of soft copper tubes minimizes the risk of leaks, providing enhanced durability and preventing potential damage to surrounding structures.

Parameters of Soft Copper Tube

| OutsideDiameter | WallThickness | NominalWeight (kgs) | Packing | |||

| inch | mm | mm | 15 Meters | 15.24 Meters | Carton Dimension(cm³) | Coils perCarton |

| 3/16 | 4.76 | 0.8 | 1.33 | 1.35 | 40*40*18.5 | 16 |

| 1/4 | 6.35 | 0.8 | 1.86 | 1.89 | 40*40*18.5 | 12 |

| 1/4 | 6.35 | 1.0 | 2.25 | 2.28 | 40*40*18.5 | 12 |

| 5/16 | 7.94 | 0.8 | 2.40 | 2.44 | 40*40*18.5 | 10 |

| 5/16 | 7.94 | 1.0 | 2.91 | 2.96 | 40*40*18.5 | 10 |

| 3/8 | 9.52 | 0.8 | 2.93 | 2.98 | 45*45*18.5 | 8 |

| 3/8 | 9.52 | 1.0 | 3.58 | 3.64 | 45*45*18.5 | 8 |

| 1/2 | 12.7 | 0.8 | 4.00 | 4.06 | 50*50*18.5 | 6 |

| 1/2 | 12.7 | 1.0 | 4.91 | 4.99 | 50*50*18.5 | 6 |

| 5/8 | 15.88 | 1.0 | 6.25 | 6.35 | 55*55*18.5 | 5 |

| 3/4 | 19.05 | 1.0 | 7.58 | 7.70 | 60*60*18.5 | 4 |

| 7/8 | 22.22 | 1.0 | 8.91 | 9.06 | 65*65*18.5 | 3 |

Soft Drawn Copper Tube Specifications

| Item | Soft drawn copper tube & pipe | |

| Standard | ASTM, DIN, EN, ISO, JIS, GB | |

| Material | T1, T2, C10100, C10200, C10300, C10400, C10500, C10700, C10800,C10910, C10920, TP1, TP2, C10930, C11000, C11300, C11400, C11500,C11600, C12000, C12200, C12300, TU1, TU2, C12500, C14200, C14420,C14500, C14510, C14520, C14530, C17200, C19200, C21000, C23000,C26000, C27000, C27400, C28000, C33000, C33200, C37000, C44300,C44400, C44500, C60800, C63020, C65500, C68700, C70400, C70600,C70620, C71000, C71500, C71520, C71640, C72200, etc. | |

| Shape | Round, Coil, Square, Rectangular, etc. | |

| Specifications | Round | Wall thickness: 0.2mm~120mm |

| Outside Diameter: 2mm~910mm | ||

| Square | Wall thickness: 0.2mm~120mm | |

| Size: 2mm*2mm~1016mm*1016mm | ||

| Rectangular | Wall thickness: 0.2mm~910mm | |

| Size: 2mm*4mm~1016mm*1219mm | ||

| Length | 3m, 5.8m, 6m, 11.8m, 12m, or as required. | |

| Hardness | 1/16 hard, 1/8 hard, 3/8 hard, 1/4 hard, 1/2hard, full hard, soft, etc | |

| Surface | mill, polished, bright, oiled, hair line, brush, mirror, sand blast, or as required. | |

| Price Term | Ex-work, FOB, CFR, CIF, etc. | |

| Payment Term | T/T, L/C, Western Union, etc. | |

| Delivery Time | According to order’s quantity. | |

| Package | Export standard package: bundled wooden box, suit for all kinds of transport, or be required. | |

Applications of Soft Copper Tubes

Soft copper tubes find extensive application across diverse industries, including:

- Plumbing: They are widely used in plumbing systems for transporting potable water, offering a safe and reliable solution for residential, commercial, and industrial applications.

- Refrigeration and Air Conditioning: Soft copper tubes serve as essential components in refrigeration and air conditioning systems, facilitating the circulation of refrigerants to regulate temperature effectively.

- Medical Gas Systems: In healthcare facilities, copper tubes are employed for medical gas delivery, ensuring the safe and efficient distribution of gases such as oxygen and nitrogen.

- Fire Sprinkler Systems: Copper tubes play a crucial role in fire sprinkler systems, delivering pressurized water to extinguish fires swiftly and effectively.

Installation Techniques of Soft Copper Tube

Proper installation is paramount to maximize the performance and longevity of soft copper tubes. Here are some key installation techniques:

- Bending: Use specialized bending tools to achieve smooth bends without kinking or flattening the tube.

- Flaring: Employ a flaring tool to create a conical flare at the end of the tube, ensuring secure connections with fittings.

- Soldering: Clean the tube and fittings thoroughly, apply flux, and use a suitable solder alloy to create leak-proof joints.

- Support: Provide adequate support for the tubing to prevent sagging or strain, especially in vertical or overhead installations.

- Pressure Testing: Conduct pressure tests to verify the integrity of the installation and identify any leaks before commissioning the system.

Maintenance Practices Soft Copper Tube

Regular maintenance is essential to preserve the functionality and efficiency of soft copper tube systems. Here are some maintenance practices to follow:

- Visual Inspection: Periodically inspect the tubing for signs of corrosion, damage, or leaks, and address any issues promptly.

- Cleaning: Remove any debris or contaminants from the surface of the tubes to prevent obstruction of flow and maintain optimal performance.

- Leak Detection: Utilize leak detection techniques such as pressure testing or ultrasonic inspection to identify and rectify leaks before they escalate.

- Protection Against Mechanical Damage: Install protective covers or guards in areas where the tubing is exposed to potential mechanical damage, such as sharp edges or heavy machinery.

- Chemical Treatment: In environments prone to chemical exposure, consider implementing corrosion inhibitors or protective coatings to enhance the longevity of the tubing.

What is copper tubing used for?

Copper tubing is a versatile material used in a wide range of applications across various industries. Here’s a breakdown of its uses:

- Plumbing: Copper tubing is commonly used in plumbing systems for both residential and commercial buildings. It is ideal for carrying hot and cold water due to its resistance to corrosion, high thermal conductivity, and durability. Copper tubing is often found in water supply lines, distribution pipes, and fixtures such as faucets and showerheads.

- HVAC (Heating, Ventilation, and Air Conditioning): In HVAC systems, copper tubing is used for refrigerant lines that carry coolant between the condenser, compressor, evaporator, and other components. Its excellent heat transfer properties make it an ideal choice for efficiently transferring heat in air conditioning and refrigeration systems.

- Medical Gas Systems: Copper tubing is used in medical gas systems to deliver gases such as oxygen, nitrogen, and medical air to patients in hospitals, clinics, and other healthcare facilities. Its cleanliness, reliability, and resistance to corrosion make it suitable for this critical application.

- Industrial Applications: Copper tubing finds numerous industrial applications, including process piping, heat exchangers, and fluid transportation systems in chemical processing plants, manufacturing facilities, and refineries. Its resistance to corrosion and high temperature make it suitable for transporting various fluids and gases in industrial settings.

- Electrical Wiring: While not technically tubing, copper wire is closely related to copper tubing in terms of material properties and applications. Copper wiring is extensively used in electrical systems for its excellent conductivity, reliability, and malleability. It is used in residential, commercial, and industrial buildings for power distribution, lighting, and telecommunications.

- Automotive and Transportation: Copper tubing is used in various automotive applications, including brake lines, fuel lines, and hydraulic systems. Its resistance to corrosion and high-pressure capabilities make it an ideal material for these critical components in vehicles, aircraft, and other transportation systems.

- Art and Decorative Applications: Copper tubing is also used in art and decorative applications due to its aesthetic appeal and malleability. It can be shaped, bent, and soldered to create intricate designs, sculptures, and architectural elements.

Soft copper tubes are indispensable components in various industries, offering unmatched versatility, durability, and reliability. Understanding their properties, applications, installation techniques, and maintenance practices is crucial for ensuring optimal performance and longevity. By adhering to proper installation and maintenance protocols, stakeholders can harness the full potential of soft copper tubes to meet the diverse needs of residential, commercial, and industrial sectors across India.

Mcneil Instruments stands out as a reputable Manufacturer, supplier, and Exporters of soft copper tubes in India, offering a wide range of good quality products to meet the diverse needs of customers across the country. With Mcneil Instruments‘ commitment to excellence and reliability, stakeholders can trust in the superior quality and performance of their soft copper tubes, ensuring peace of mind and satisfaction in every installation. Whether for plumbing, refrigeration, air conditioning, or other applications, Mcneil Instruments remains a trusted partner in providing soft copper tube solutions throughout India.