FORGED GLOBE VALVES THREADED

Globe Instrumentation Valve Manufacturers, Suppliers, Exporters in India

Globe valves consist of a movable disk-type element and a stationary ring seat in a generally spherical body. The valve stem moves a globe plug relative to the valve seat. The globe plug can be at any position between fully opened and fully closed to control flow through the valve. The globe and seat construction gives the valve good flow regulation characteristics. Turbulent flow past the seat and plug, when the valve is open, results in a relatively high pressure drop, limited flow capacity, and low recovery.

Products

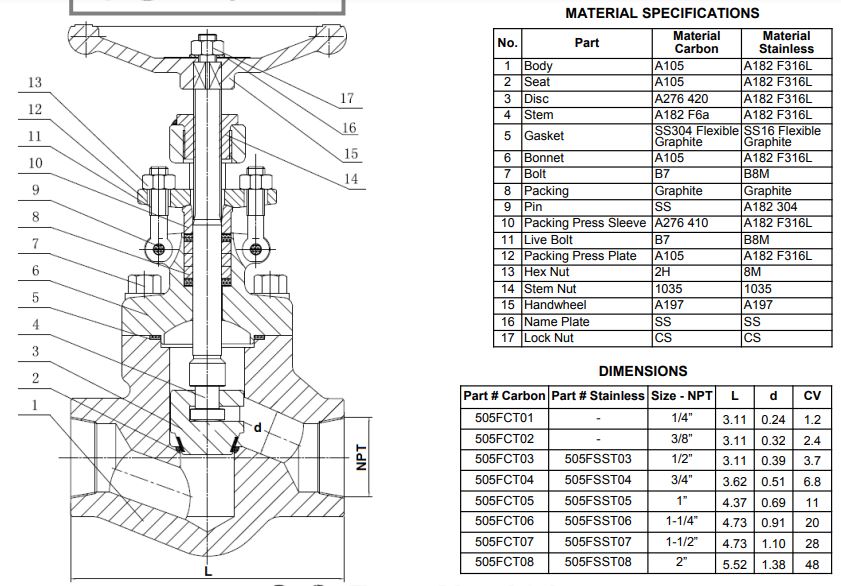

Parts of a Typical Globe Valve

- Body: Main structure containing ports for fluid entry/exit. Configurations include straight and angled (90°) ports to prevent clogging and corrosion.

- Bonnet: Provides a leak proof closure; may be screw-in, union, or bolted for durability.

- Plug/Disc: Regulates flow by connecting to the stem. Available in balanced (holes through the plug) or unbalanced (solid) types for different flow and pressure needs.

- Stem: Connects the actuator to the plug. Designed for high strength to handle compression and tensile forces; often has packing to prevent leaks.

- Cage: Surrounds the plug, guiding it to the seat. Controls flow rate by exposing cage openings as the plug moves.

- Seat: Offers a stable, replaceable shut-off surface, often beveled for smooth closure.

Stainless Steel Globe Valve

Mcneil Instruments Inc. is one of the Best Stockiest of Stainless Steel Instrumentation Globe Valve in India

Alloy Steel Globe Valve

| Connection Size | 1/4″ – 1″ |

| Pressure Rating | 6000 – 10,000 psi |

| Temp. Range | -40°C up to 230°C |

The ‘PV’ Series rising plug valve provides bubble-tight isolation with a regenerative soft seat. It also has a clear bore, a high flow, and precise control, making it roddable. Excellent for usage under high pressure with viscous materials.

Carbon Steel Globe Valve

| Connection Size | 1/4″ – 1″ |

| Pressure Rating | 6000 – 10,000 psi |

| Temp. Range | -40°C up to 230°C |

The ‘AV’ Series 90° angle pattern needle valve provides high pressure bubble tight sealing in a small body and enables pipe work origination to alter by 90° at the valve.

Hastelloy Globe Valve

| Connection Size | 1/4″ – 3/4″ |

| Pressure Rating | 6000 – 10,000 psi |

| Temp. Range | -40°C up to 230°C |

Due to the nearly straight bore through the valve, the ‘OB’ Series has significantly less pressure drop and flow restriction than a typical needle valve. The inclined head unit and handle make it user-friendly. especially beneficial when used with heavy or viscous fluids.

Duplex Steel Globe Valve

| Connection Size | 1/4″ – 3/4″ |

| Pressure Rating | 6000 – 10,000 psi |

| Temp. Range | -40°C up to 230°C |

The ‘GV’ Series multiport gauge valve features vent and blanked port facilities as well as additional drains, making it an effective way to attach pressure gauges, manometers, pressure transducers, or transmitters in a circuit or system.

High pressure Globe Valve

| Connection Size | 1/4″ – 1″ |

| Pressure Rating | 6000 – 10,000 psi |

| Temp. Range | -40°C up to 230°C |

A single isolation hand valve from the precisely engineered “UN-V” Series uses a metal-to-metal seat and body-to-bonnet connection for better, bubble-tight sealing at high pressures and temperatures.

What is Globe Instrumentation Valve

A globe instrumentation valve is a type of valve used to control the flow of liquids or gases in industrial systems. It consists of a movable disk (or plug) that regulates the flow by either opening or closing the passage inside the valve. The disk is connected to a stem that can be manually turned or operated by an actuator (like a motor or solenoid) to adjust the flow rate. This valve design allows for precise control over the amount of fluid passing through, making it suitable for applications where accurate regulation of flow and pressure is crucial, such as in refineries, chemical plants, and process industries.

For good quality globe instrumentation valves, trust Mcneil Instruments. As leading globe instrumentation valve manufacturers, suppliers, and exporters, we ensure best products designed for reliability and performance. Contact us today to discuss your valve requirements and discover how we can meet your industrial needs effectively.

Different Types of Globe Instrumentation valves

Manufacturer of 316 stainless steel and carbon steel 2way, 3way, and 4way needle valves. Available in sizes ranging from 1/4 to 1 in., with an operating pressure of 10,000 psi and a temperature range of 0 to 1000 °F. Non-rotating ball chairs, bubble-tight shut-offs, and handles are features. Suitable for gauge port applications, general shut-off lines, and process control lines. serves the petrochemical, chemical, oil and gas, and power sectors. fulfills ANSI, ASME, and ASTM requirements.

How Globe Instrumentation Valve Work

Globe valves work simply and effectively by using a handwheel or actuator to move a disc closer to or farther away from a seat inside the valve. This movement controls how much fluid can flow through. When the disc is lifted completely, the valve opens fully, allowing maximum flow. On the other hand, lowering the disc completely shuts the valve, stopping the flow completely.

Best Globe Valves Manufacturers, Suppliers, & Exporters in India

With a wealth of expertise, Mcneil Instruments Inc. stands out as a premier manufacturer, supplier, and exporter of needle valves in India. Our extensive range of needle valves caters to diverse industries such as chemical, steel, petrochemical, fire safety, paper, shipping, and conveyance sectors. These valves are meticulously engineered using high-quality raw materials and adhere to stringent global quality standards.

Best Stainless Steel Valves Manufacturers, Supplier, & Exporter in India

Globe Instrumentation Valve Manufacturers, Globe Instrumentation Valve Suppliers, Globe Instrumentation Valve Exporters, Best Globe Instrumentation Valve Manufacturers in India

- Precise flow regulation<

- Frequent and wide throttling operation

- Suited to very high pressure drops

- Efficient and precise throttling

- Accurate flow control

- Suitable for most liquids, vapors, gases, corrosive substances

- General sizes available are 1/2″ to 8″

- Pressure limitations are relatively high, ranging from 1480 to 1500 psi, dependent on materials of construction, size and temperature.

- Minimum and maximum temperatures are also very broad ranging from -425°F to 1100°F, depending again on the materials of construction.

- Depending on the specific construction and application, the globe valve may comply with ASME class II, III, IV, V or VI shut-off requirements.

Monel :

Grade: Monel 400, Monel K500, Monel R-405

Nickel :

Grade: Nickel 200, Nickel 201

Inconel :

Grade: Inconel 600, Inconel 601, Inconel 625, Inconel 718

Incoloy :

Grade: Incoloy 800, Inconel 800H, 800HT

Hastalloy :

Grade: Hastalloy B2, Hastalloy B3, Hastalloy C22, Hastalloy C276, Hastalloy X

Titanium :

Grade: Gr1, Gr2, Gr3, Gr5, Gr7, Gr11

Stainless Steel :

Grade: ASME / ASTM SA / A403 SA / A 774 WP-S, WP-W, WP-WX, 304, 304L, 316, 316L, 304/304L, 304H, 316H, 316/316L, 321, 330, 347, 309/S, 310/S, 317/L, 333, 410/S, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404

Carbon Steel :

Grade: ASTM A 234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70

Duplex Steel:

Grade: ASTM / ASME A/SA 182 UNS F44, F45, F51, F53, F55, F60, F61

Alloy Steel:

Grade : ASTM SA 182 – E25, E26, E27, E28, E29B, E30B, E39B, E40B, E36B, E36C, E41B, AISI4130, AISI4140, AISI4340, 42CRMO4, 16MNCR5, 20MNCR5, 21CrMoV57, EN353, EN354, F11, F22, F91, F9, P11, P22, P91, P9, P5, P92, EN42J, EN8, EN19

| Description | Features |

| Type | One Piece / Two Piece / Three Piece |

| End Connection | Threaded: NPT, BSPT, BSPP / Welded: Butt Weld, Socket Weld / Flanged: ANSI, DIN |

| Size | 1/4” to 2” (DN 6 to DN 50) |

| Pressure Rating | Up to 15,000 PSI (1,000 bar) |

| Temperature Range | -120°C to 500°C (Range varies as per pressure) |

| Body Materials | Body: Stainless Steel (SS316, SS304) / Ball: Stainless Steel (SS316) / Seats: PTFE (Teflon), PEEK / Seals: PTFE, Viton, Buna-N |

| Design Standards | API 598 (Valve Inspection and Testing), ISO 9001 (Quality Management), ASME B16.34 (Valves – Flanged, Threaded, and Welding End) |

| Face to Face | ASME B16.10 (Rev 2009) |

| Safety Compliance | NACE MOR 0175, BS/EN 10204-3.1 (Rev 2004), API 598 (Rev 2009), API-607 |

| Operational Benefits | Designed for precise fluid and gas control, ensuring reliable performance in critical applications. |

| Compact Design | Space-saving design ideal for instrumentation panels and confined installations. |

| Flow Control Options | Available options for minimal pressure drop or controlled flow as per requirements. |

| Ease of Use & Maintenance | Simple design allows for easy manual operation and straightforward maintenance. |

| Corrosion Resistance | High-quality stainless steel body ensures durability in harsh environments. |

| Versatile Connections | Various end connections to accommodate different piping and system requirements. |

| Reduced Component Wear | Operates with minimal effort, reducing component wear and extending valve lifespan. |

| Safety Features | Anti-blowout stem and secure locking mechanisms prevent accidental operation. |

| Leak Prevention | Ensures bubble-tight shutoff to maintain system integrity and prevent leaks. |

| Temperature & Pressure Suitability | Operable across a wide range of temperatures and pressures, suitable for versatile applications. |

| Customizable Options | Custom configurations and material selections available to meet specific application requirements. |

Mcneil Instruments’ Globe Instrumentation Valves are designed for reliability, safety, and adaptability across diverse and demanding environments, ensuring top performance and longevity.